The Innova series of Fagor DRO’s represents a new technological breakthrough in measuring and control systems for machine-tool customers. Their advanced features and excellent qualities are the ideal choice for the machine tool with very competitive prices. Innova series DRO’s offer many advanced features, in some cases, features exclusive to Fagor Automation. These exclusive features are at our customers’ disposal as a standard option. Knowing applications has made it possible to develop these features in order to increase the productivity of milling machines, boring mills, lathes and grinders among other applications.

The Fagor M series for Milling and Boring machines come in either 2, 3, or 4 axis systems. The 20iM (2-axis) and the 30iM (3-axis) systems come in a variety of sizes for any size milling machine. The 40i (2 or 3-axis) and the 40iP (2, 3, or 4-axis) come in a full color display with a variety of functions.

IF YOU DON’T SEE THE SIZE YOU ARE LOOKING FOR PLEASE Call us at 800-285-5271

Please call or email for current availability

1-800-285-5271 / 260-422-0020

Please call or email for current availability

1-800-285-5271 / 260-422-0020

Please call or email for current availability

1-800-285-5271 / 260-422-0020

The Fagor T series for Lathes come in either 2 or 3 axis systems. The 20iT (2-axis) systems come in a variety of sizes for any length lathe. The 40i (2-axis) and the 40iTS (2-axis) come in a full color display with a variety of functions.

IF YOU DON’T SEE THE SIZE YOU ARE LOOKING FOR PLEASE Call us at 800-285-5271

.

Please call or email for current availability

1-800-285-5271 / 260-422-0020

Please call or email for current availability

1-800-285-5271 / 260-422-0020

Innova series FAGOR DRO’s carry components created, developed and patented by Fagor Automation. Highly reliable products that adapt to the customers’ particular needs in order to improve the productivity of milling machines, boring mills, lathes, grinders, EDM and general purpose applications among other machines.

Please call for price and availability.

10i Specifications (General Purpose):

10i-E Specifications (EDM and Grinders):

Please call for price and availability.

20i Specification (General Purpose):

20i-M Specifications (Milling):

Same as above plus:

20i-T Specifications (Turning):

20i-E Specifications (EDM and Grinders):

Please call for price and availability.

30i-M Specifications(Milling):

30i-T Specifications (Turning):

30i-E Specifications (EDM and Grinding):

Please call for price and availability.

40i Specifications:

40i-P Specifications (Milling):

40i-TS Specifications (Turning):

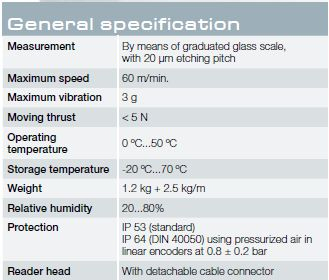

Fagor sealed linear encoders provide a robust and reliable solution for applications requiring high levels of positional control in demanding operating conditions and environments. The mechanical, electronic and optical designs of the linear encoders ensure consistency in technical specification and functional characteristics and minimize the effect of machine errors.

CALL FOR PRICING AND AVAILABILITY 1-800-285-5271

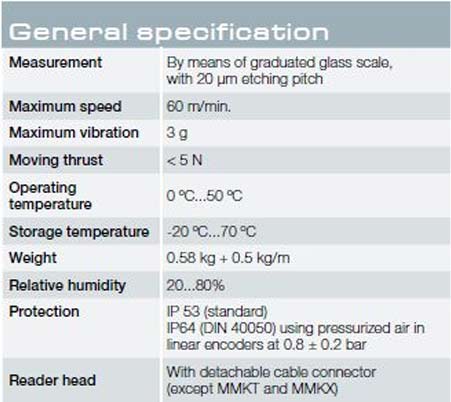

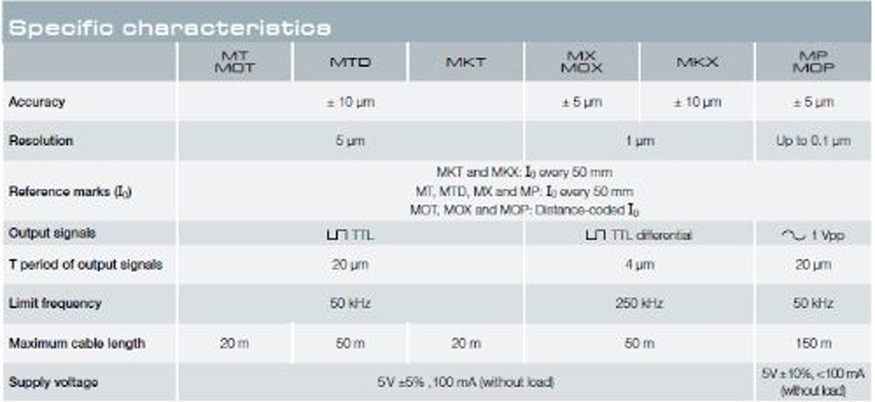

(MT, MOT, MTD, MKT, MX, MOX, MKX, MP, MOP)

Please call for price and availability. 1-800-285-5271

Designed for applications on standard machines with travels up to 60.63 in. With reference marks every 1.97 in or distance-coded and detachable cable connector built into

the reader head (except the MK series where the reader head comes standard with a 3-meter attached cable).

Measuring lengths in inches

1 (*) • 2 • 4 • 5 • 6 • 8 • 10 • 12 • 14

16 • 18 • 20 • 24 • 28 • 30 • 32 • 36 • 40

44 • 48 • 52 • 56 • 60

(*) On MT and MX models.

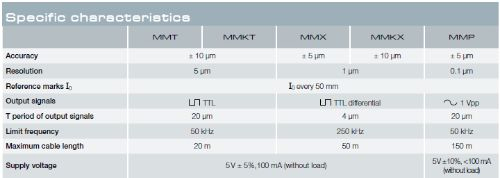

(MMT, MMKT, MMX, MMKX, MMP)

Please call for price and availability. 1-800-285-5271

Designed for applications on standard machines with travels up to 20.47 in. With reference marks every 1.97 in and a detachable cable connector built into the reader head (except the MMK series where the reader head comes standard with a 3-meter attached cable). With very small profile, .2 in less than the M series they are ideal for tight spaces.

Measuring lengths in inches

1 (*) • 2 (*) • 4 • 5 • 6 • 8 • 10 • 12 • 14

16 • 18 • 20

(*) On MMT and MMX models.

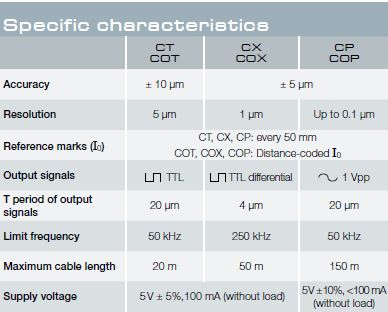

(CT, CX, CP, COT, COX, COP)

Please call for price and availability. 1-800-285-5271

Designed for applications on standard machines with travels up to 119.67 in. With reference marks every 1.97 in or distance-coded and detachable cable connector built into the reader head.

Measuring lengths in inches

8 • 10 • 12 • 14 • 16 • 18 • 20 • 24 • 28 • 30

32 • 36 • 40 • 44 • 48 • 52 • 56 • 60

64 • 68 • 72 • 76 • 80 • 88 • 96 • 102

110 • 118

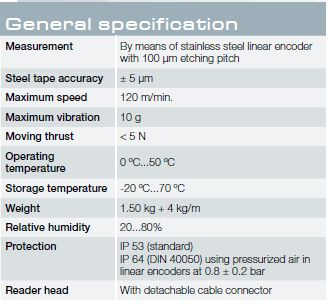

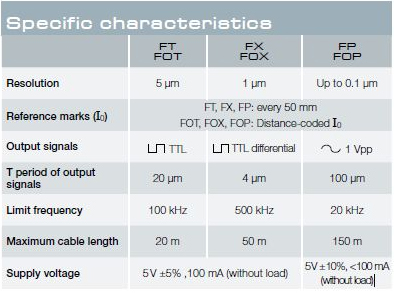

(FT, FX, FP, FOT, FOX, FOP)

Please call for price and availability. 1-800-285-5271

Especially designed for machines with longer travels and they are available up to 98.4 ft in length. In the incremental model the reference marks are 1.97 in apart and distance coded model is also available. Both models come with a detachable cable connectors in the reader head. The steel tape graduation pitch is 100 μm. For measuring lengths over 159 in the encoder is supplied in multiple sections and is assembled together at the time of installation.

Measuring lengths in inches:

• Measuring lengths from 17.32 in to 98.4 ft in 7.87 in increments.