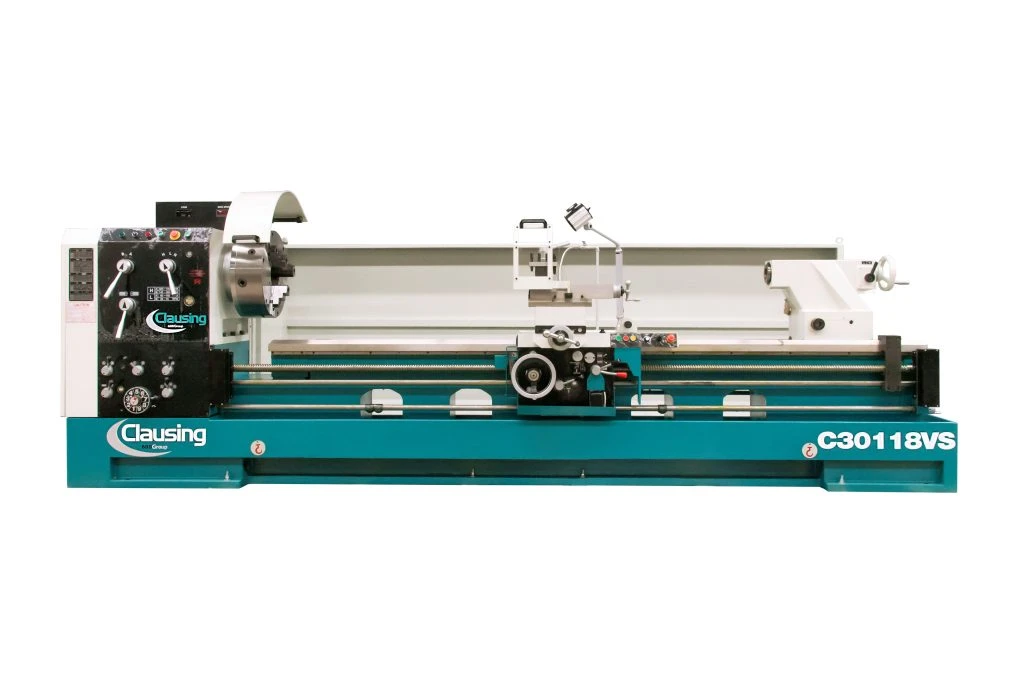

Clausing variable speed lathes are the industry standard. The quality built into every machine translates into real long term performance for your application. The removable gap plate allows for large face plates to be mounted onto the spindle nose for various turning applications. Camlock Spindles, a wide range of spindle speeds, full length rear splash guard with coolant system, and inch/metric threading make this machine a must have for any machine shop.

Variable speed head lathes use a belt drive system from the motor to gearbox head. Speed changes are then selected by inverter drive, 4 range speed selection, and potentiometer 25-1000RPM.

Three phase voltage refers to three individual lines that connect to and run voltage through the motor. Each line alternates in a sequence as it reaches its voltage peak. This provides for a more stable flow of voltage and more horsepower to the machine.

Available with 43″, 63″, 79″, 118″ or 157″ Center Distance.

Available with a 12 Speed Geared Head or Variable Speed Head

- A2-11 Spindle nose

- 3 Step Inverter drive spindle speeds allow optimum cutting speed for a wide range of machining applications. Speed range 14-1000 rpm

- 20 Hp Spindle Motor for exceptional machining power

- All gears are made from chromium molybdenum steel treated with cementation and precision ground for long life and dependability

- One piece cast iron bed from the ways to the floor provides a solid foundation to ensure maximum stability and rigidity under heavy machining operations

- 18” Bed Width, harden and ground, support the saddle and carriage assembly allowing superior positioning and repeatability accuracy

- Turcite “B” is fitted between the saddle and bed to greatly reduce friction and stick-slip for smooth operation and superior surface finishes. The low friction Turcite ”B” also minimizes bed wear and extends the life of the machine

- Immersing style lead screw reduces abrasion

- 4-way rapid traverse for positioning and setup

- 4-way power feed for longitudinal, cross, and compound feeds

- Tailstock with 4.18” quill, manual positioning for ease of setup and operation

- 4.125” spindle bore supported with taper spindle bearings provides outstanding spindle performance and load carrying capabilities (optional bore sizes available)

- Coolant system for tool life and part cooling

- Automatic Lubrication system to all guideways

- Guarding powder coated for durability

- Full rear splash guard with chip pan

- A one year warranty backed by Clausing Service Center dedicated to support our customers with parts and service